Sep. 28, 2019

Sep. 28, 2019

As a Metal CNC Parts Manufacturer, let's share with you the requirements for CNC machining precision.

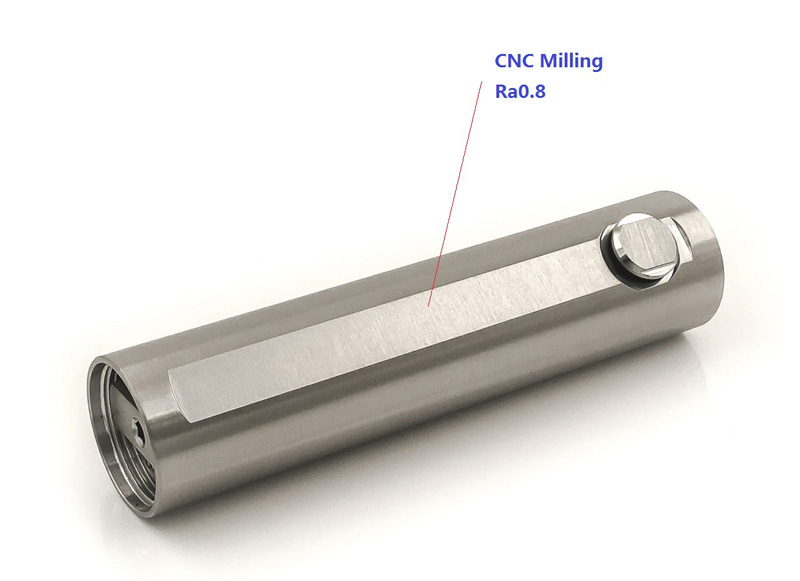

How does the surface roughness of CNC machined metal parts reach 0.8?

Use a milling cutter with a large diameter to make the rotation speed as high as possible, but the machine tool can't be shocked. The rough milling leaves 0.3-0.5mm and then finishes the finishing. Can it be enough to reach the speed of the milling cutter? The blade is sharp or not. The milling cutter head with a large diameter is for easy to achieve high line speed, and the light increasing speed does not increase the diameter of the milling cutter disc. In general, it is possible to achieve a roughness of 0.8. In addition, a sufficient amount of cutting fluid is added during finish milling.

CNC Machining Part

What is the surface roughness of CNC machining?

Generally, ordinary machine tools are processed at about 3.2, and high-speed machines can achieve a finish of 1.6; pay attention to the tools and cutting parameters used in machining.

The smaller the surface roughness value of Aluminum Machining Part, the finer it is?

1. About the profiler and the roughness meter profiler and the roughness meter are not the same product. The main function of the profiler is to measure the contour shape of the surface of the part.

For example the groove depth, groove width, chamfer (including chamfer position, chamfer size, angle, etc.) of the groove in the automobile part, and the straightness of the surface of the cylinder surface. In short, the profiler reflects the macroscopic profile of the part.

2. The function of the roughness meter is to measure the surface processing quality of the grinding/finishing process on the surface of the part. Generally speaking, it is the smoothness of the surface of the part, that is, the roughness reflects the microscopic condition of the surface of the part.

Our company specializes in providing Metal CNC Machining Services. If you want to know more details, please feel free to contact us, we will be happy to help you.

Previous: Rapid Prototype Aluminum Parts

Previous: Rapid Prototype Aluminum Parts