Send us your CAD files to get a free quote for custom sheet metal

prototypes and production parts, precision quality and lead times

as fast as days.

● Free quote with DFM report within 1 day

● Sample first for confirmation

● Lead time as fast as 3 days

Xu Feng provides a fast and cost-effective solution for sheet metal fabrication services, offering a range of materials and fabrication processes. Choose Xu Feng as your supplier to expedite your product development cycle with swift delivery of sheet metal prototypes and production parts. You can receive sheet metal parts in as fast as 1 day and simple metal components within a 3-day lead time.

|

|

|

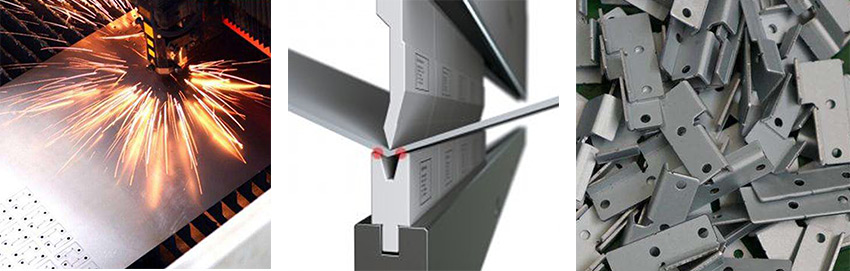

Laser CuttingLaser cutting is a manufacturing process that employs a high-power laser to precisely cut sheet metals, forming various geometries. This technology enables fast and accurate processing, facilitating the creation of intricate designs with a wide range of metals. | BendingBending is a metal fabrication process that shapes flat sheet metal into V, U, or channel forms using a press brake machine. This method ensures high precision and repeatability with minimal setup costs, allowing for the creation of complex geometries | Welding and RivetingGas metal arc welding(MIG) or gas tungsten arc welding(TIG) as well as CNC welding are possible on sheet metal parts at Xu Feng. Riveting is an available secondary sheet metal process at Xu Feng also, which increased flexibility. |

Fast-track your product development cycle with sheet metal prototypes and production parts at Xu Feng. Benefit from expedited flat sheet metal parts delivered in as little as 1 day and simple formed sheet metal components within a lead time of 3 days, offering a variety of materials.

|

|

|

|

Our Sheet Metal Fabrication ProcessAfter receiving your design files, our engineers provide a quote and optimize your drawing. The design drawing is converted into precise machine code. Following cutting, bending, and stretching, the thin metal sheet is shaped to meet your desired specifications. Additionally, welding, riveting, and fastening can be performed to produce the end-use product that meets your unique requirements. We adhere to strict quality standards throughout the entire process. |

Sheet Metal Fabrication Material Options(1) Aluminum (2) Stailness Steel (3) Steel or Galvanized Steel (4) Brass (5) Copper (6) Titanium |

Sheet metal is the basis for many low cost fabrication processes and is one of the most common raw materials in manufacturing. Parts can be bent into numerous useful configurations. Minimal material is used in comparison with parts machined from block material. Parts that you might otherwise think must be made from block material can often be redesigned to adapt to sheet metal form. For example you can often use bending instead of milling. Stacking sheets of same shape can achieve higher thickness. Stacking sheets of different shapes can build up a desired 3D shape. Combining sheet metal processes with other processes such as milling a recess in a laser cut sheet can achieve more flexibility.

Sheet metal is widely used for numerous industrial and non-industrial applications including: fuselages, wings, auto body panels, auto trim parts, bumpers, doors, chassis, brackets, appliances, boilers, kitchen equipment, office equipment etc. alloys.

We can quote your job using conventional CAD files or you can use our unique free CAD software where you can: design your part quickly and easily, get instant pricing, and order online.