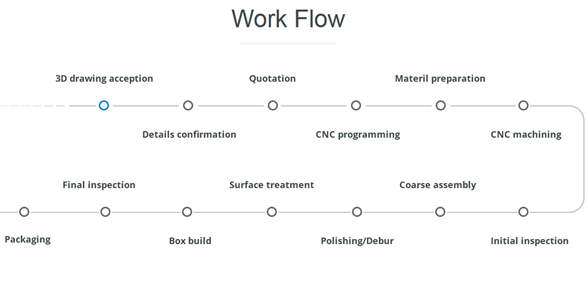

Are you searching for a reliable supplier for metal and plastic projects? Xu Feng provide services from prototypes to on-demand production parts. You can receive instant quotes and choose from 40+ materials and 10+surface finishes. Our domestic and imported facilities, equpped with 3, 4 5-axis as well as compound CNC machining centers with quick-change tooling,are programmed using advanced UG/CAD/PROE/SOLIDWORKS software to ensure reliable and quick-turn production. We offer advanced capabilities, including tighter tolerances, cost-saving pricing, and performace parts tailored to your requirements.

★ Instant quotes within hours ★ Free DFM feedback based on your drawing ★ Tolerances down to ±.0004’’(0.01mm) ★ Prototypes in as fast as 5-7 days ★ Cost-efficient pricing for parts in larger volume ★ On time delivery |

|

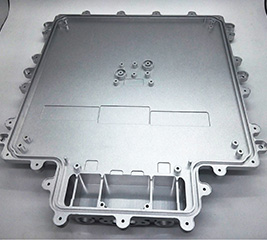

CNC milling, with muti-axis capabilities including 3,4, and 5-axis machining, offers precision in crafting detailed geometries from metal or plastic blocks. This subtractive manufacturing process utilizes 3-axis and 5-axis indexed milling to transform solid blocks into final parts, automating the cutting process with rotating spindle-heads. Suitable for a variety of materials, CNC milling machines create machined surface finishes on metals or plastics, and are versatile for producing custom parts, from intricate 3D shapes to precision cuts in materials ranging from many kinds of plastic and aluminum to stainless steel, copper, brass, titanium and so on.

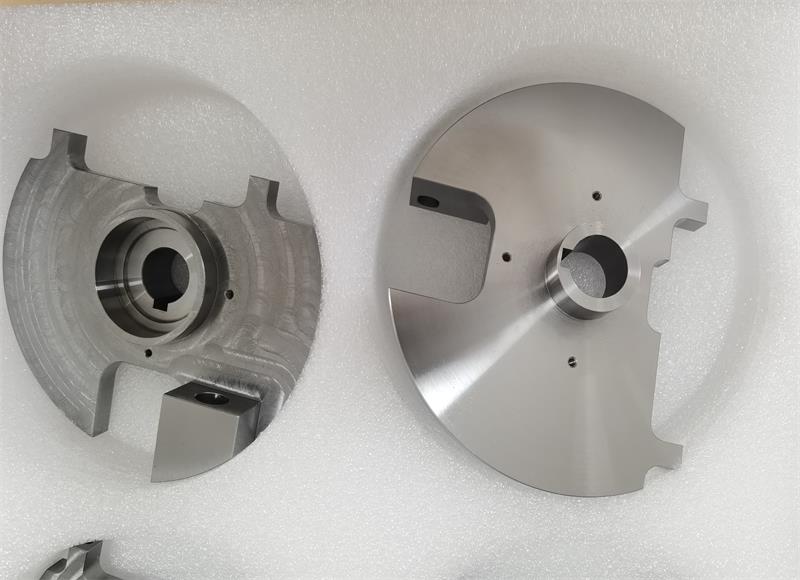

CNC Turning with live tooling seamlessly combines lathe and mill capabilities to precision-machine cylindrical features from metal or plastic rod stock. This process, also known as CNC lathe machining, excels in cutting symmetrical cylindrical or spherical parts. Utilizing a spinning workpiece and a moving shaping instrument, the act of cutting on a CNC lathe is termed turning. In this manufacturing process, material bars are securely held in a chuck, rotated, and fed into a tool to shape the desired form. The turret, with attached tooling, is programmed to remove material from the raw bar, achieving the specified result.

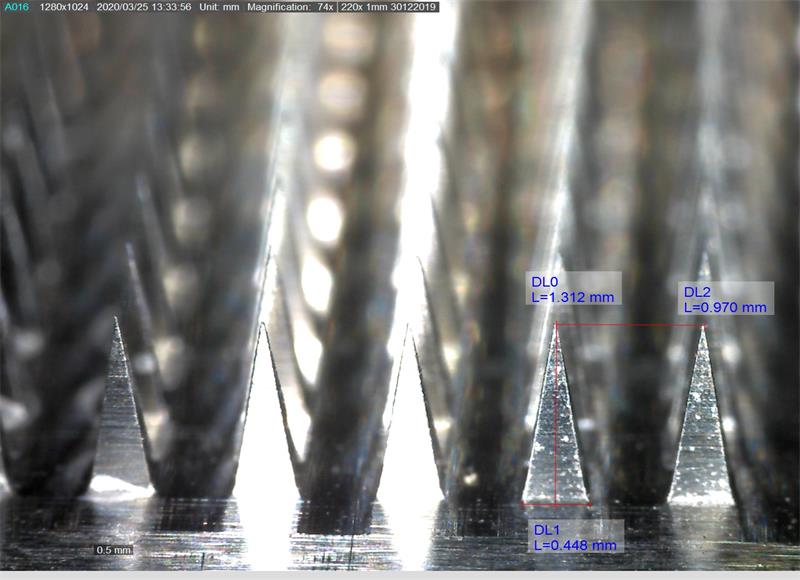

EDM (electrical discharge machining) is a technique where electrical sparks shape and carve through conductive materials. In precision manufacturing, wire EDM stands out as a process that offers high accuracy and intricate detailing. Xu Feng specializes in EDM services, employing cutting-edge technology to create holes, pockets and surface textures in hardened steel, Particularly for mold tools. Our facility is equipped with Sodick wire cutting and EDM machines, offering various speeds to cater to diverse client needs.

Additionally, we provide surface grinding and cylindric grinding services. During surface grinding, the workpiece is held stationary on a horizontal plate, and the surface grinding wheel is computer-controlled to abrade the workpiece to a precise depth.

Xu Feng excels in mastering Wire EDM and Grinding, leveraging years of experience and innovation to deliver unparalleled precision machining solutions. We assist numerous clients in achieving μm-level processing. Our mission is to push boundaries and set new benchmarks, ensuring our clients receive exceptional productions that go beyond market expectations.

Xu Feng machines parts according to the tolerance specified on 2D drawings per clients' requirements. During the quoting process, our skilled engineers check the critical tolerance and inform you if we can achieve it. In the absence of specific tolerance requests, we adhere to the general tolerance table for CNC machining, with metal tolerance follwing DIN 2786-fH and plastic tolerances following DIN 2768-mK.

It's important to note that tolerances can be influenced by the part structure and material type. Our sales team will consult with you on every aspect of your project, striving to deliver the highest precision possible.

Xu Feng is capable of working with a wide range of plastic and metal materials, offering our clients numerous of options based on their application. We provide instant quotations of 40+ commercial-grade metals, plastic material, additionally, we provide machining special material such as wooden and carbon fiber plate.

|

|

|

CNC Metal MaterialsAluminum, Steel Alloy, Stainless Steel, Copper, Brass, Titanium and more | CNC Plastic MaterialDerlin(POM), ABS, Acetal, Nylon, PP, HDPE, PEEK, PTFE, PVC and more | CNC Special MaterialWooden, Carbon Fiber, Epoxy board FR4 and more |

With a range of materials and finishing options, coupled with guaranteed quality ensured by advanced inspection equipments, you can trust us to deliver exceptional parts every time. Once you send us the 3D or 2D file, our engineers will assess its manufacturability, ensuring that the part can be made to your expectations and budget requirements. Inquiry us today for a free quote!

Contact us for a free quote on CNC machining services from a China supplier today!

Skype: dreamfly830

E-mail: sales@xftooltech.com

Web: https://www.xfcncparts.com