Xufeng, with over 20 years of expertise, specializes in the fabrication of plastic injection molding parts and molds. A notable 98% of our output is dedicated to export markets. Our comprehensive services include tooling design and construction within our workshop, the machinery employed spans a range from 30t to 1200t, facilitating the production of prototypes and fulfilling on-demand manufacturing needs, volume production runs.

♣ Free quote within one day

♣ DFM report with moldflow anaysis and design key points

♣ Free T0 samples as fast as one weeks for the test

♣ Mold modification based on testing result

♣ 0.05mm mold tolerance

| Injection molding tool | injection molding part | Insert Molding | Overmolding |

|

|

|

|

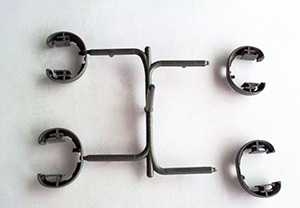

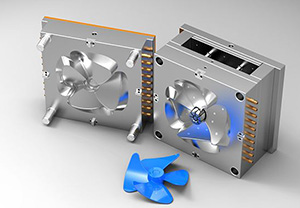

| Injection molding tools are precision molds used in manufacturing. Consisting of mold cavity and core halves, they shape molten material into products. Essential for mass production, these tools ensure efficiency and accuracy. | Plastic injection molding is a manufacturing process where molten plastic is injected into a mold, forming a solid shape upon cooling. Widely used for mass-producing plastic parts, it ensures precision and efficiency. | Insert molding is a manufacturing method where a pre-made component, like metal or plastic, is placed in a mold. Molten material, often plastic, is then injected to encapsulate the insert, creating integrated products. | Overmolding is a manufacturing process where a base object is covered with a second material, often plastic, enhancing functionality and aesthetics. It creates seamless, multi-material products for improved durability and design. |

Injection molding stands out as the most cost-effective method for large-scale plastic part production. The process entails injecting molten plastic into a mold tool, yielding solidified parts after ejection. With the ability to repeat this process numerous times, it amortizes the mold tool cost, reducing unit costs to a few dollars or less. The consistent use of the same mold tool ensures uniform quality across all parts. Moreover, injection molding provides a broad range of materials, colors, cosmetics, polishes, and surface textures, surpassing options available in CNC machining or 3D printing.

Our plastic injection molding process produces custom prototypes to high-volume end-use production parts. Get bulk pricing & DFM in 1 day. 30+ thermoplastic, thermoset materials.

| injection molding is videly used for plastic part productiom in consumer, medical and automotive industry, typical parts include: Industrial Aerospace Construction and Building Materials Sporting Goods Consumer Goods Automotive Industry Electronics Medical Devices |

Plastic injection molding offers servral advantages, making it a widely used manufacturing process for producing plastic parts from low- to high-volume production. Cost effective for mass production Complex Geometry and Precision Consistency and Reproducibilit Expectional surface Finish and Appearance Reduced Waste Material Variety High Efficiency and Speed |  |

Injection Molding Tool Materials Before the production of the injection molding process, a high tolerance machined tool is required. the most commonly used materials include: |

|

Thermoplastic Materials A plastic injection molding service offers a wide range of materials with various properties, including impact strength, rigidity, thermal resistance, chemical resistance, and more. ABS, PP, PC, PBT, PA, PMMA, PET, POM, PS, PEEK, AAS, PVC, HDPE, PTFE, TPU, Nylon and so on |  |

Thermoset Several thermoset materials for various applications due to their unique properties, such as high heat resistance, dimensional stability, and excellent electrical insulating properties. Silicone Rubber, Polyurethane, EPE, Epoxy, Phenolic |  |

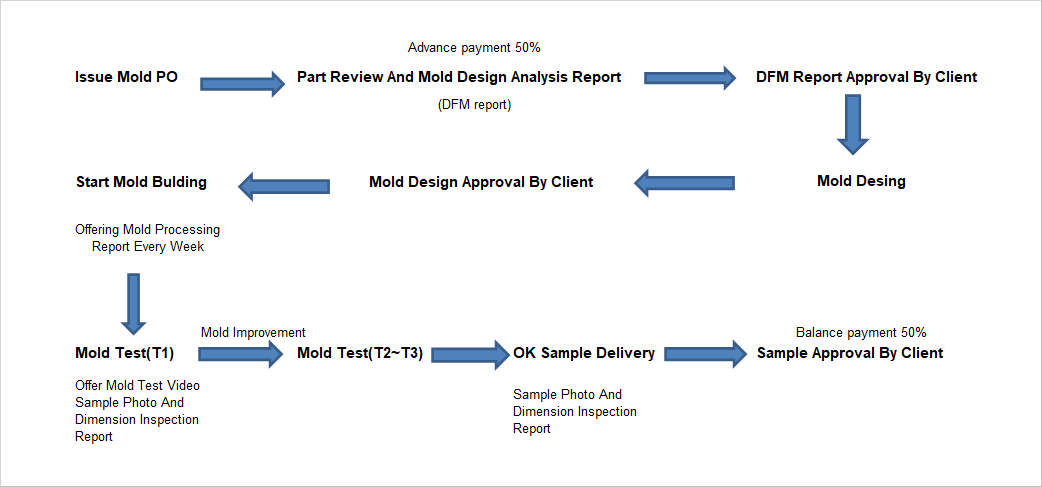

See how Xu Feng Processes your order, from PO receipt and DFM report, to efficient injection mold tooling, mold testing, sample confirmation, ensuring the delivery of quality-satifying product with our skilled team and machinery.

♣ Free DFM report

Every quote includes real-time pricing and free DFM report. our skilled engineers evaluate your part design file and help identify the features that may pose challenges during molding process such as the difficult to machine undercuts and insufficient draft and give the advise to improve it.

♣ No MOQ

Producing parts on demand, without MOQs, offering a cost-effective solution for managing market fluctuations, addressing emergencies, this helps move the process from design to production in a fast turnaround and supports you on-demand needs with reduced cost.

♣ Fast turnaround

With a strong supplier chain and an experienced engineering team, we accelerate the product development cycle and bridge plastic parts production by weeks, sometimes months, In certain cases, small injection molding orders can be shipped in as fast as 1 day.

♣ Injection molding expertise

Our plastic injection molding engineering team, with over 20 years of experience, will collaborate with you throughout your project, facilitating a swift transition from prototyping to mass production. This includes support in mold design, material and surface finish selections, and the provision of inspection reports.

♣ Stable and high quality

Conducting in-process inspections, and performing dimensional verification after production, we ensure the consistency of custom-molded parts, regardless of complex shapes, with high precision

Inquiry Your Plastic Injection molding Project Today

Upon receipt of your 3D model file, our engineers will conduct a comprehensive review, taking into account factors such as draft angles, wall thickness, corner angles, material type, and more to optimize it for manufacturing. We also ensure the appropriate combination of materials with design considerations, ensuring that your project not only meets but exceeds your expectations. Contact us today for a free quote.

Plastic Injection Molding Service

Plastic Granulation Process

Plastic Injection Molding Process

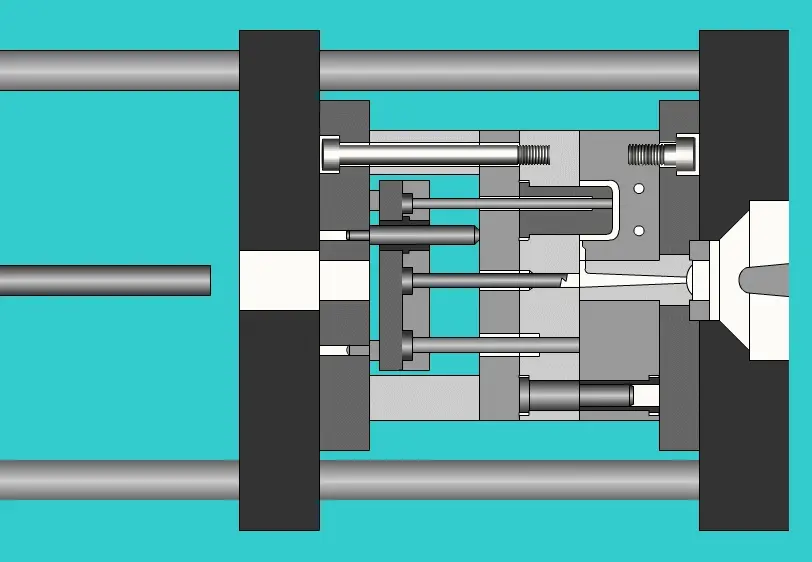

Plastic Injection Tooling