Jun. 03, 2020

Jun. 03, 2020

In the field of mechanical processing, the turning and milling complex

machining center unanimously plays a very important role. It can realize the

functions that conventional CNC lathes and CNC milling machines cannot achieve.

At present, many machining manufacturers in Shenzhen have assembled them. In

addition to use, we also need to perform periodic maintenance on it. What are

the main components that need to be maintained in the turning-milling machining

center? Take a look with CNC Turning Milling Parts Factory.

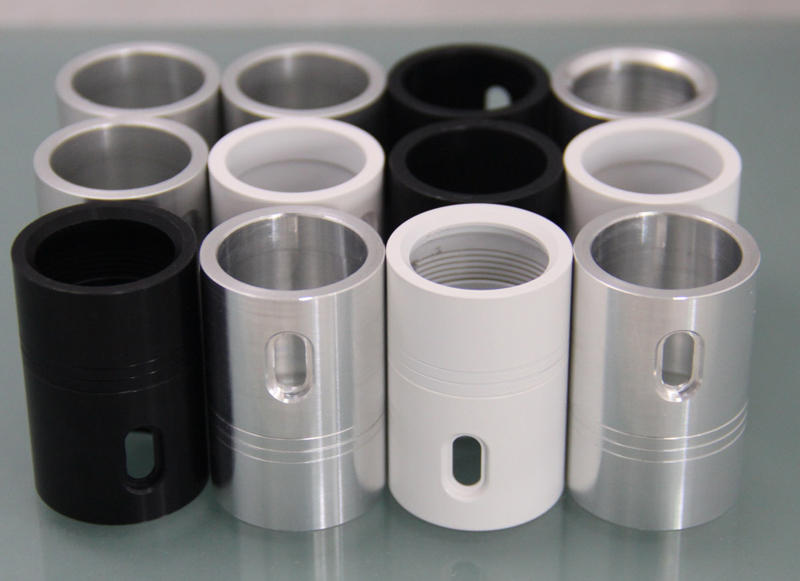

CNC Aluminum Milling Parts

The ball and screw of the turning and milling compound center

1. Pay attention to avoid cutting chips, dust, impurities and other particles from entering the vice working area of the screw, resulting in damage to the screw;

2. The ball screw is a moving accessory part. It must be fully lubricated to avoid oil loss and dry friction to damage the ball screw. When the machine tool uses large flow cooling, pay attention to increase the ball screw lubrication frequency and flow to avoid screw rust;

3. Do not allow the nut to exceed the stroke limit;

4. Strictly prevent collisions, resulting in damage to the displacement of the ball screw nut return, which affects accuracy and produces noise;

The servo motor of the turning and milling compound center

1. When equipped with servo motor or frequency conversion speed regulation, according to the alarm information of the servo drive or frequency converter, it can find out the cause of the alarm and the method of eliminating the alarm, or call with our staff

2. The main motor (frequency conversion motor or two-speed motor) and drive motor (stepping motor or servo motor) should pay attention to moisture. If the motor enters water, it will cause a short circuit between the motor phases and burn the motor; Causing damage to the servo motor encoder;

3. When the machine tool is not used for a long time, the main power supply should be cut off, and the machine tool should be continuously operated for 2 to 3 hours at least once a month;

4. When using frequency conversion, after cutting off the AC power, before the indicator of the digital operator of the AC motor driver is not extinguished, it means that there is still high voltage inside the AC motor driver. It is very dangerous. Do not touch the internal circuits and components. Power off for 5 minutes Then operate again;

Spindle of turning and milling complex machining center

1. When the temperature difference between the spindle spindle and the bushing is too large, the spindle bearing is likely to burn out. The temperature setting of the oil cooler must be set according to the temperature in winter and summer;

2. In order to ensure the long-term smooth operation and service life of the spindle, please hand over the machine after handing over the machine to ensure the service life of the spindle;

Our company manufacture CNC Turning Milling Parts for sale, please contact us.