Nov. 01, 2021

Nov. 01, 2021

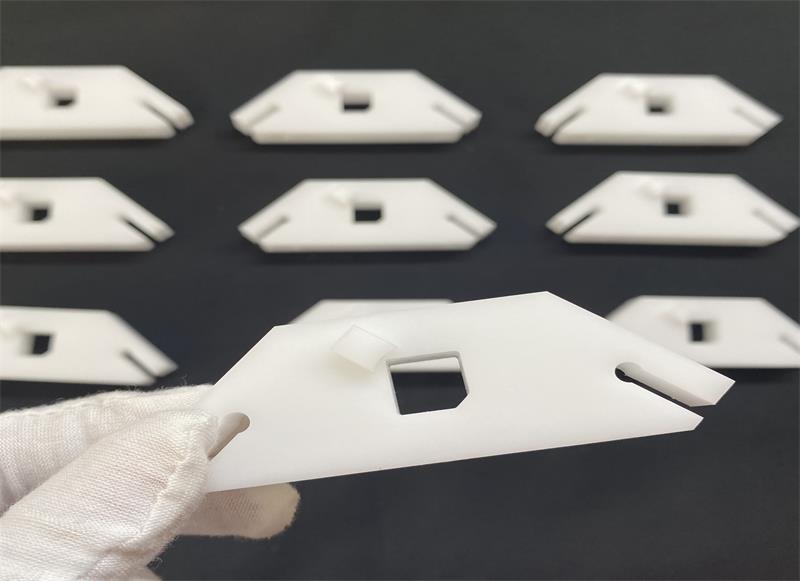

Xu Feng Has rich experience in CNC machining parts, here we shared the main unavoidable factors which will affect the accuracy of the finished products during machining and what measurements do we generally take to maintain the size of the parts, pls. follow us to understand.

1. Cooling method

The thermal expansion and contraction deformation of the parts during the machining is unavoidable. Therefore, we should pay attention to the cooling effect, and increase the frequency of on-machine measurement, base on the analysis data, choose the right cooling medium and cooling method.

2. Performance of the machines

Mechanical processing is definitely inseparable from machine tool equipment. Over time, the processing of different materials will change the performance of the machine tool, which will further affect the machining accuracy. The first is the guide error of the guide which mainly causes the parts to move in the sensitive direction of the machine error, resulting in straightness and flatness errors on the surface of the aluminium machining parts. Then the rotation error of the machine tool spindle during rotation, the original main axis of the main shaft, and the coaxially and roundness errors are caused to the cylindrical surface of the processed parts. Hardware precision machining is the final error of the transmission chain of the machine tool. The position of the machine tool will change during the transmission of the part, thereby forming the error of the part displacement. The hole on the surface of the machined part, the table and some auxiliary structures cause the position error and degrees error.

Therefore, strict requirements must be placed on the equipment, real-time operation status of the equipment should be mastered, some variable factors appearing in the machining process should be strictly controlled, and the dimensional qualification of the parts should be checked carefully and responsibly.

If you are still worried about the processing of precision parts, please contact us, we'll help you with it.

Previous: Rapid Prototype Aluminum Parts

Previous: Rapid Prototype Aluminum Parts