Oct. 24, 2022

Oct. 24, 2022

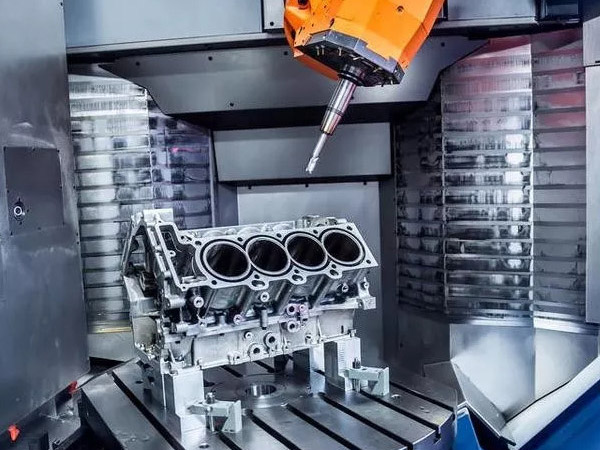

CNC stands for Computer Numeric Control, and CNC machining refers to the processing carried out with CNC machines. CNC machine plays an essential role in the manufacturing industry because of their stable machining quality, high machining accuracy, complex surfaces machining capability, and high machining efficiency. The best CNC machining services providers use advanced CNC machines for complex and precision machining parts.

The most common CNC machines are categorized into vertical and horizontal. Although their appearance and structure are the same. In general, a CNC machine mainly composes of the following parts.

1, Basic components

The basic structure of a CNC machine tool consists of a bed, a column and a worktable. They are the basic components of a CNC machining center. These components are basically cast irons, which are used in CNC machining centers to withstand static loads and dynamic loads during machining. Therefore, the rigidity of the bed casting must be very high, and they are very important components that determine the quality of the CNC machining center.

2, CNC Spindle

The CNC spindle unit consists of parts such as headstocks, spindle motor, spindle and spindle bearings. The start, stop and speed change of the spindle are all controlled by the CNC system, and the cutting tool is involved in the cutting motion through the tool mounted on the spindle. The spindle unit is the power output component of the machining process.

The spindle is the key component of the CNC machining center. The quality of its structure has a great influence on the performance of the CNC machining center, which determines the machining accuracy and stability.

Due to the large load, high speed and high precision requirements of CNC machining centers and high-speed CNC milling machines, the ordinary spindle double-direction bearing structure can no longer meet the requirements. Now for high-speed machining centers and CNC milling machines, angular contact bearing combination design is mostly used. Because angular contact bearings can bear radial and axial loads in one direction at the same time, the allowable limit speed is higher. Two angular contact ball bearings are assembled back-to-back, so that the support points A and B expand outward, shorten the overhang of the spindle head, greatly reduce the deflection of the spindle end, and improve the spindle rigidity.

Getting off the topic, mini and small CNC machines (desktop CNC machines) are now very popular for people who love DIY work. The spindles of these CNC machines use high-quality miniature ball bearings for their rotating components.

3, Computer Numeric Control System

The CNC (Computer Numeric Control) system of CNC machining center is composed of a CNC device, a programmable controller PLC, a server drive system and an operation panel. They are the control center of CNC machines that perform sequential control actions and complete operations during machining.

The CNC device is a position control system. The control process is to perform data processing and interpolation operations according to the input information to obtain the ideal motion trajectory information and then output it to the execution components to process the required workpieces.

The function of the server system is to convert the signal from the numerical control device into the movement of the moving parts of the machine. Its performance is one of the main factors that determine the machining accuracy, surface quality and production efficiency of the machine. CNC machining centers generally use three control methods: semi-closed loop, closed loop and mixed loop.

4, Automatic Tool Changer

The automatic tool changer consists of tool magazine, manipulator, drive mechanism and other components. During the machining process, when the tool needs to be changed, the CNC system issues an instruction, and the manipulator (or by other means) takes the tool out of the tool magazine and loads it into the spindle hole. It solves the tasks of automatic storage, selection, transportation and exchange of tools between processes in the multi-process continuous processing after the workpiece is clamped once.

The tool magazine (tool head) is a device that stores all the tools used in the machining process. The tool magazine has disc type, chain type, etc., and the capacity ranges from a few to dozens.

The structure of the tool arm also has various forms according to the relative position and structure of the tool magazine and the spindle, such as single-arm type, double-arm type, etc. Some do not use the tool arm but directly use the movement of the spindle box or the tool magazine to realize the tool change.

5, Auxiliary Device System

The Auxiliary Device System includes lubrication, cooling, chip removal, protection, hydraulic, pneumatic and detection units and other parts. The auxiliary system plays a decisive role in guaranteeing the machining efficiency, machining accuracy and reliability of the CNC machining center even though it does not directly participate in the cutting motion. Therefore, it is an indispensable part of the CNC machining center.

Conclusion

This article has walked you through knowledge of the 5 main components of CNC machines. There are many factors which can decide the machining precision level of the CNC machine. And the precision level of the CNC machine and the worker’s skill & experience decide the precision level of the CNC machining parts. So, you need to know about the CNC machining services provider’s equipment and facility condition if you are looking for CNC machining services for your project.

Xufeng Tool Tech provides high precision CNC machining services to worldwide customers since 2003. Our factory is equipped with the most advanced CNC machines and experienced employees and can make the best CNC machining parts for you at an effective cost. Please contact us to get a no-obligation quotation for your CNC machining project today.