Aug. 02, 2023

Aug. 02, 2023

In the modern world, we are surrounded by countless household items that make our daily lives more convenient and comfortable. Many of these items, such as kitchen utensils, storage containers, and bathroom accessories, are made using Injection Moulding of Rubber and Plastic. This manufacturing process has revolutionized the production of household parts, providing cost-effective, durable, and versatile solutions. XuFeng This article delves into the features, benefits, and applications of Injection Moulding of Rubber and Plastic for household parts, showcasing its pivotal role in enhancing everyday convenience.

hot tags: CNC Milling Part,CNC Turning Part,CNC Aluminum Part

1. Features of Injection Moulding of Rubber and Plastic

Injection Moulding is a versatile and efficient manufacturing process that offers several key features:

1.1 Precision and Consistency

Injection Moulding ensures high precision and consistency in the production of household parts, resulting in uniform products with minimal variation.

1.2 Material Versatility

The process can handle a wide range of materials, including various types of rubber and plastic, allowing manufacturers to choose the most suitable material for specific household parts.

1.3 Complex Shapes and Designs

Injection Moulding allows for the creation of intricate and complex shapes, enabling designers to produce innovative and functional household items.

1.4 Cost-Effectiveness

The ability to produce large quantities of household parts quickly and efficiently makes Injection Moulding a cost-effective manufacturing process.

2. Benefits of Injection Moulding of Rubber and Plastic

Injection Moulding of Rubber and Plastic offers several benefits that contribute to its widespread use in household part production:

2.1 Durability and Longevity

Household items made through Injection Moulding are known for their durability and longevity, withstanding everyday wear and tear.

2.2 Customization

The flexibility of Injection Moulding allows for easy customization, enabling manufacturers to tailor household parts to specific customer preferences.

2.3 Lightweight and Versatile

Household parts made from plastic are often lightweight and versatile, making them easy to handle and use in various settings.

2.4 Consistent Quality

The precision and consistency of Injection Moulding ensure that each household part meets stringent quality standards, providing consumers with reliable and high-quality products.

3. Applications of Injection Moulding of Rubber and Plastic for Household Parts

Injection Moulding of Rubber and Plastic finds widespread applications in producing a wide range of household items, including:

3.1 Kitchen Utensils

From spatulas and ladles to food storage containers, Injection Moulding produces a wide array of kitchen utensils that are durable and easy to use.

3.2 Bathroom Accessories

Toothbrush holders, soap dishes, and shower caddies are commonly made using Injection Moulding, offering practical solutions for organizing bathroom essentials.

Injection Moulding of Rubber and Plastic has played a pivotal role in transforming household part production, making everyday convenience more accessible to people worldwide. The precision, consistency, and cost-effectiveness of this manufacturing process have enabled the creation of durable, versatile, and customized household items. From kitchen utensils to bathroom accessories, Injection Moulding has enriched our daily lives with practical and reliable solutions. As technology and materials continue to advance, Injection Moulding will continue to be a driving force in household part production, ensuring that our homes are equipped with functional, innovative, and durable items that enhance our everyday experiences.

3.3 Household Containers

Plastic bins, boxes, and jars used for storage and organization are efficiently produced through Injection Moulding.

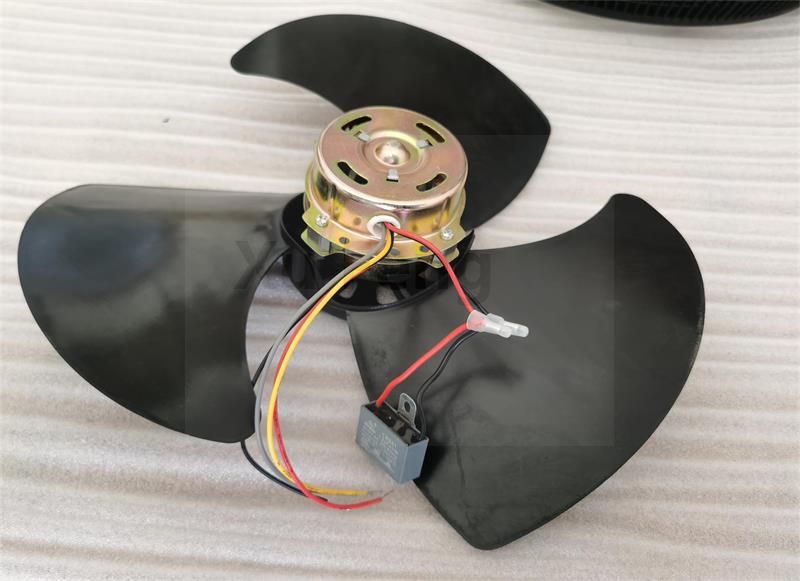

3.4 Home Appliances

Many components of home appliances, such as blender lids, vacuum cleaner parts, and coffee maker components, are manufactured using Injection Moulding.

Injection Moulding of Rubber and Plastic has played a pivotal role in transforming household part production, making everyday convenience more accessible to people worldwide. The precision, consistency, and cost-effectiveness of this manufacturing process have enabled the creation of durable, versatile, and customized household items. From kitchen utensils to bathroom accessories, Injection Moulding has enriched our daily lives with practical and reliable solutions. As technology and materials continue to advance, Injection Moulding will continue to be a driving force in household part production, ensuring that our homes are equipped with functional, innovative, and durable items that enhance our everyday experiences.