Dec. 16, 2022

Dec. 16, 2022

Xu Feng is a manufacturer focused on customized metal and plastic parts production, we take pride in supporting our clients with relevant industry information, and every month we cover topics related to our services and capabilities. Surface treatments are necessary processes for most metal parts we manufacture, which help to prevent corrosion and improve appearance, and some of these treatments also provide enhanced mechanical or electrical properties that contribute to the overall functionality of the component. In this article, we'll show 7 commonly used surface treatment types.

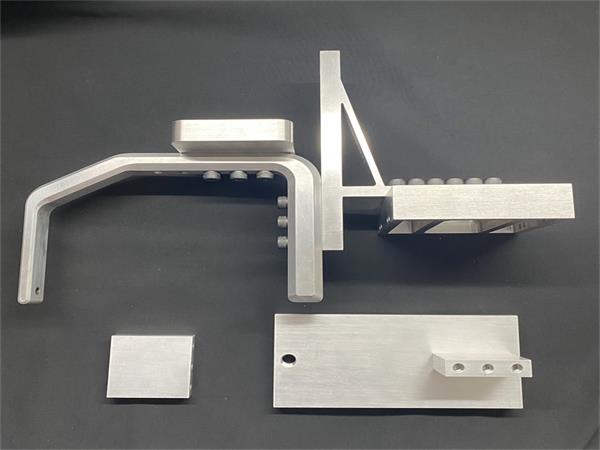

1, Anodizing

Anodizing is actually an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminium alloy is the ideal material which is suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized, it is seldom asked to do it.

Anodizing is accomplished by immersing the aluminium alloy into an acid electrolyte bath and passing an electric current through the medium. A cathode is mounted to the inside of the anodizing tank; the aluminium acts as an anode so that oxygen ions are released from the electrolyte to combine with the aluminium atoms at the surface of the part being anodized. There are two classifications, nature and colour, our company can provide various colours of anodizing.

2, Painting

Steel can't do anodizing, and instead, if you need different colours, Painting is a good choice. Usually, powder coating or spray painting is a requirement from the clients. To achieve the best results of the painting, the products need to be clean-free of oil, rust, dust, debris and so on. Anything left on your product prior to coating will affect the painting adhesion and finish, that's where pretreatment for painting needs.

If the product you want to paint has a lot of debris(rust, laser scale, machining mark), then you will likely need a shot-blasting operation. if solvents, oils or chemical residue cover the products' surface, then pretreatment needs to be considered, washing the station with some chemical agent, such as iron and then using hot water to clean it.

3, Galvanizing

Galvanizing is the process of coating the metal parts with a layer of zinc, which offers superior corrosion protection. This type of surface treatment is often used for outdoor applications and is highly durable and long-lasting.

The process involves the use of a hot-dip galvanizing method that involves dipping the metal into a solution of molten zinc. due to its low cost and effectiveness. There are two main types of galvanizing: hot-dip galvanizing and electroplating. Hot-dip galvanizing involves immersing the metal part in a bath of molten zinc, which adheres to the surface of the part. Electroplating involves immersing the part into a bath of zinc ions, which are then deposited onto the metal part. Both methods are effective in protecting the metal from corrosion, but hot-dip galvanizing is generally more durable and long-lasting. You can choose any type you would like to do with your part.

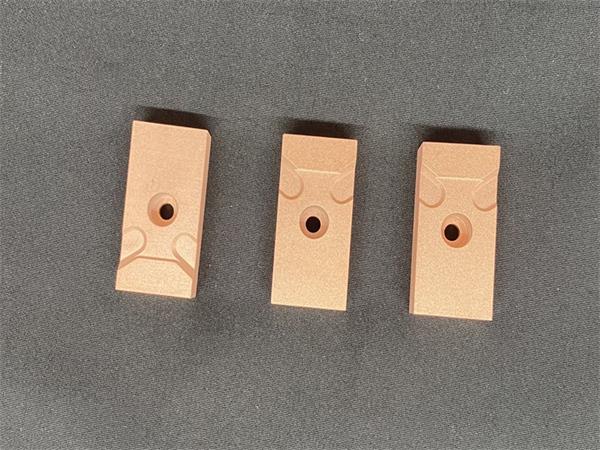

4, Powder Coating

Powder coating is commonly used on metals such as steel, aluminium, and magnesium, as well as other materials such as plastic, wood, and composites. It is a process of applying a layer of plastic powder to a metal part, which is then melted and adhered to the surface. The process typically involves pre-treating the surface of the metal part, applying the powder using an electrostatic gun, and then baking the part in an oven to melt and cure the powder.

This process provides a durable, attractive finish that is resistant to scratching, corrosion, and chemicals. Powder coating is also an environmentally friendly process, as the powder is usually made from recycled materials, and the process does not generate any hazardous waste.

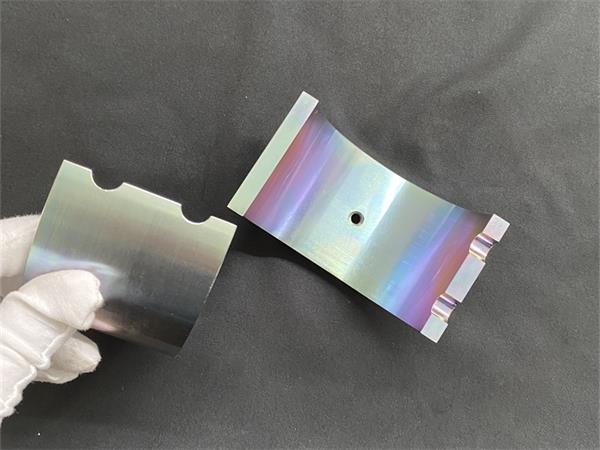

5, Plating

Plating is a process of coating a layer of metal over the surface of a metal part to enhance its corrosion resistance, wear resistance, and/or electrical conductivity. The process typically involves pre-treating the part to remove any dirt or corrosion, immersing the part in a solution of the desired metal, and then passing an electric current through the solution, which causes the metal to be deposited onto the part.

Plating provides a durable and attractive finish that is resistant to corrosion and wear and also provides improved electrical conductivity. There are many types of plating, including zinc, nickel, chrome, and gold plating. Each type of plating provides different levels of corrosion resistance, wear resistance, and electrical conductivity, so it is important to select the right type of plating for the application.

6, Sandblasting

This type of treatment is often used to remove rust and corrosion and is often used in combination with other types of surface treatments. Sandblasting is a type of surface treatment that involves the use of high-pressure air to blast particles of sand at the surface of the metal. It is best suited for a variety of surface preparation tasks such as removing old paint, rust and other forms of surface contamination. It is also used to prepare surfaces for painting and coating, as well as to give surfaces a unique textured finish.

When choosing the right sandblasting method, the main consideration is the type of material that needs to be blasted. Different materials require different kinds of abrasive materials and blasting techniques. The process involves the use of a sandblaster, which blasts tiny particles of sand onto the surface of the metal.

7, Heat Treating

Heat treatment is a process used to change the physical or chemical properties of a material by heating it to a certain temperature and then cooling it at a specific rate. Common heat treatments include annealing, hardening, tempering, and quenching.

The result of a surface or heat treatment can be measured using a variety of methods, such as surface roughness measurements, hardness tests, optical or electron microscopy, and X-ray diffraction.

When performing surface or heat treatments, it is important to follow all safety protocols and to use proper protective equipment. Additionally, it is important to follow the manufacturer's instructions for the treatment and to ensure the material is properly pre-treated and cleaned before performing the treatment.

Of course, there are many other methods of surface treatment, and we only list what we commonly do for our clients, surface treatment finish according to the client's requirement, and our professional engineers also can give some advise base on your need. For more information, please kindly contact us for it.